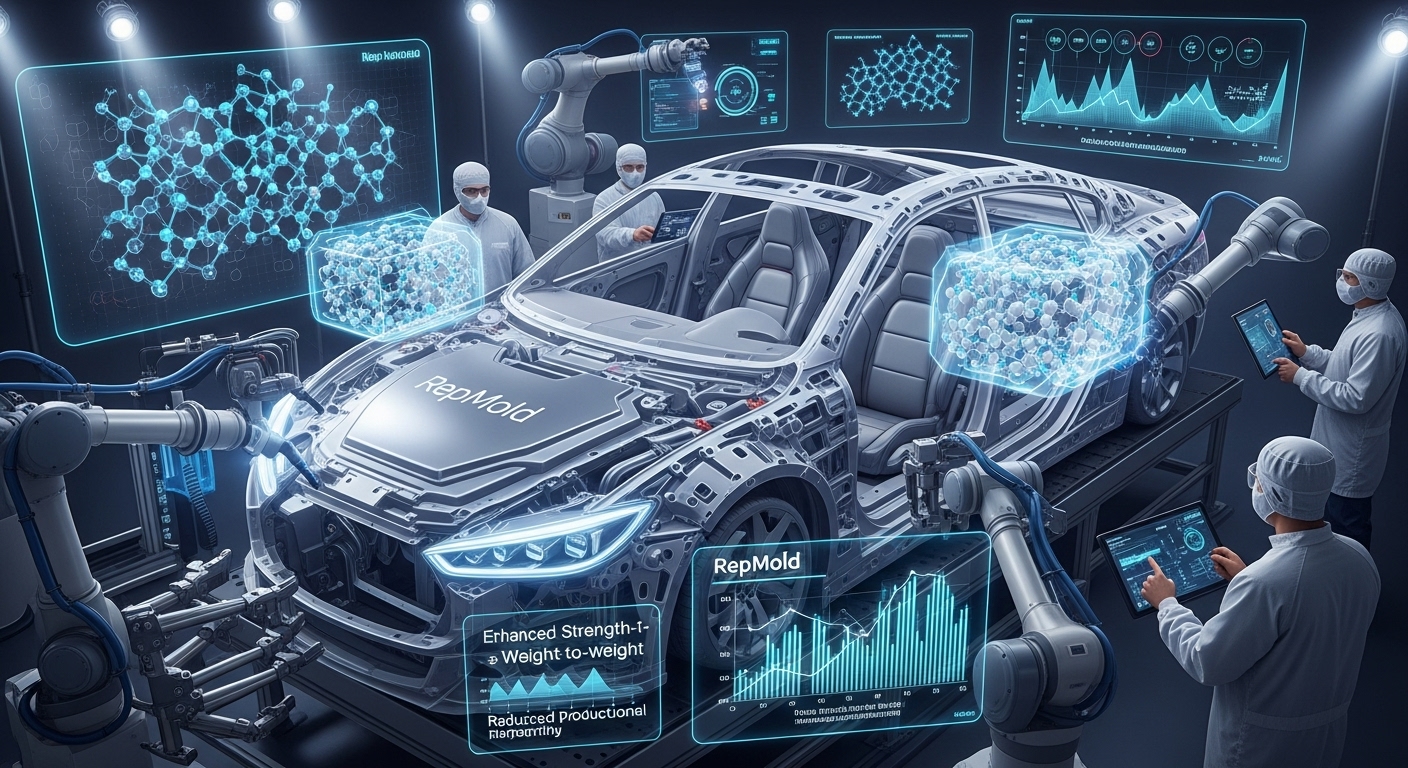

The automotive industry is on the brink of a transformative era, and at the forefront of this change is RepMold. This innovative technology promises to reshape how vehicles are manufactured, pushing boundaries that once seemed insurmountable. As the market demands faster production times and greater sustainability, companies are searching for solutions that can meet these challenges head-on. Enter RepMold—a game changer that’s not only improving efficiency but also redefining design possibilities in vehicle manufacturing. Let’s delve into what makes RepMold such an exciting development in automotive innovation.

The Need for Innovation in the Automotive Industry

The automotive industry is at a crossroads. Traditional manufacturing methods are being challenged by the demands of modern consumers and sustainability concerns. With rising environmental issues, there’s an urgent need for greener solutions. Electric vehicles alone aren’t enough; innovative processes must complement them to reduce waste and enhance efficiency.

Moreover, technology is evolving rapidly. Consumers expect smarter, safer cars equipped with advanced features that improve their driving experience. This shift requires manufacturers to adapt quickly or risk falling behind competitors. Market dynamics also play a crucial role in this landscape. Global supply chain disruptions expose vulnerabilities in conventional production methods, underscoring the necessity for agile alternatives. Innovation isn’t just about keeping pace; it drives growth and profitability within the sector. Embracing new ideas can lead to transformative advancements that resonate with both businesses and consumers alike.

How RepMold is Revolutionizing the Industry

RepMold is changing the game in automotive manufacturing. This innovative technology allows for rapid prototyping of complex parts, streamlining the production process. Traditional methods can be slow and costly, but RepMold speeds things up significantly. Using advanced materials and techniques, it creates lightweight yet durable components that improve vehicle efficiency. Manufacturers are finding they can design with greater flexibility while reducing waste at the same time.

The ease of integration into existing workflows makes RepMold appealing to companies looking to modernize their operations without a complete overhaul. As a result, businesses gain a competitive edge by cutting lead times and enhancing product quality. Moreover, its scalability means it benefits both small startups and large automakers alike. The adaptable nature of RepMold fosters innovation across various sectors within the industry.

Benefits of RepMold Technology

RepMold technology offers numerous advantages that can transform the automotive landscape. One of the most notable benefits is its ability to reduce production time significantly. By streamlining manufacturing processes, this innovative approach allows companies to bring new models to market faster. Another crucial benefit is cost efficiency. RepMold minimizes waste and lowers material costs, ultimately leading to more affordable vehicle production. This reduction can translate into savings for consumers as well.

Sustainability also plays a key role in RepMold’s appeal. The use of eco-friendly materials helps manufacturers meet regulatory standards while appealing to environmentally conscious buyers. Additionally, RepMold enhances design flexibility. Engineers and designers can experiment with complex shapes and structures previously deemed impractical, fostering creativity in automotive design. This technology not only improves functionality but also enhances aesthetics by allowing for intricate designs without compromising structural integrity.

Success Stories of Companies Using RepMold

Many companies have embraced RepMold technology, transforming their operations and boosting efficiency. One notable example is AutoFab Inc., which reported a 30% reduction in production time for complex automotive parts. This leap allowed them to meet growing market demands without compromising quality.

Another success story comes from GreenDrive Motors. They utilized RepMold to create lightweight components that improved vehicle fuel efficiency by 15%. Such advancements not only enhanced performance but also aligned with the company’s sustainability goals.

Additionally, SpeedyParts Ltd. implemented RepMold in their prototyping process. The result was quicker iterations and lower costs, enabling faster product launches and gaining a competitive edge in the marketplace. These real-world applications showcase how RepMold is reshaping industry standards and pushing boundaries across various sectors within automotive manufacturing.

Future Outlook and Potential Impact on the Industry

The future of RepMold in the automotive industry looks promising. As production technology continues to advance, manufacturers are increasingly adopting this innovative solution. RepMold offers versatility that traditional methods simply cannot match. This flexibility allows for rapid prototyping and customization, meeting consumer demands more efficiently than ever before.

Sustainability is another key aspect driving its adoption. With growing environmental concerns, RepMold’s eco-friendly materials significantly reduce waste during manufacturing processes. Moreover, as electric and autonomous vehicles gain traction, the need for lightweight components becomes crucial. RepMold’s ability to create durable yet light parts positions it at the forefront of this shift. As more companies invest in this technology, we can expect a transformative wave across supply chains and design philosophies within the automotive sector. The ripple effects could redefine how vehicles are conceived and built altogether.

Conclusion

RepMold is making waves in the automotive industry, and its impact cannot be overstated. This innovative technology addresses many challenges faced by manufacturers today, offering solutions that enhance efficiency and drive sustainability. As more companies recognize the advantages of RepMold, we can expect a shift toward smarter production methods. The success stories emerging from businesses that have adopted RepMold highlight its transformative potential. These organizations are not only improving their bottom lines but also setting new standards for environmental responsibility within the sector.

Looking ahead, it’s clear that RepMold will play a crucial role as the automotive landscape continues to evolve. Its ability to streamline processes while minimizing waste positions it as a leader in future innovations. The journey of integrating such advanced technologies has just begun and promises exciting developments for both manufacturers and consumers alike. As we move forward into this new era of automotive innovation, keeping an eye on advancements like RepMold will be essential for anyone invested in the industry’s future.